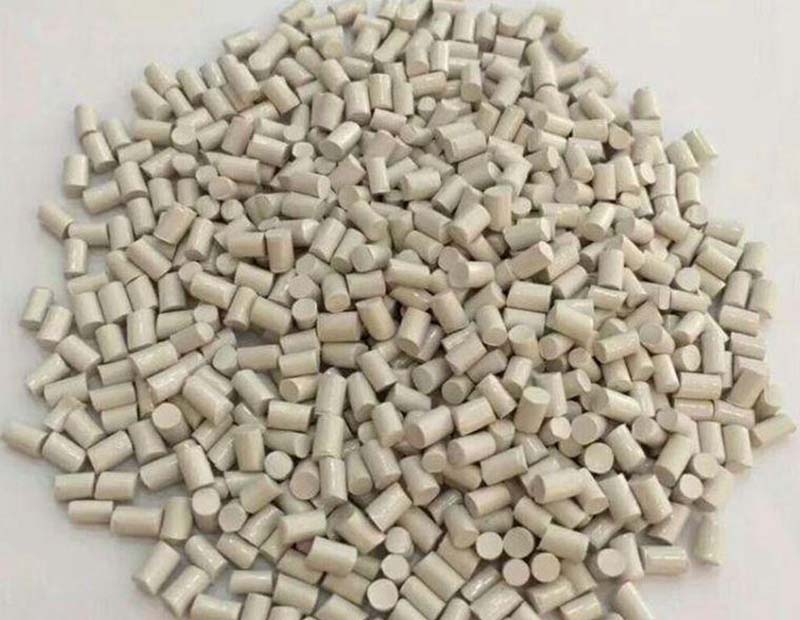

As a leading PEEK manufacturers and supplier, we specialize in delivering high-quality PEEK Material for demanding industrial applications. PEEK Polyetheretherketone, also known as polymer PEEK, is a High-performance thermoplastic that combines exceptional mechanical strength, chemical resistance, and thermal stability. Our PEEK plastic and PEEK plastic material solutions are trusted by manufacturers worldwide for precision parts, medical devices, electronics, and aerospace components.

What Is PEEK Material?

What is PEEK material? PEEK, or polyetheretherketone, is a semi-crystalline, high-temperature engineering polymer. Known for its outstanding strength, stiffness, and chemical resistance, PEEK plastic maintains its properties even under continuous exposure to temperatures up to 250°C.

Common industry references include:

PEEK polyetheretherketone

PEEK plastic material

Plastic PEEK material

Polymer PEEK

What Material Is PEEK Made Of?

What is PEEK material made of?

PEEK is synthesized from monomers of ether and ketone groups, forming a linear aromatic polymer chain. This unique molecular structure gives PEEK its remarkable combination of:

High thermal resistance

Excellent mechanical strength

Chemical inertness

Low wear and friction

Key Features of PEEK Plastic Material

High Temperature Resistance – Continuous service up to 250°C and short-term exposure to 300°C.

Excellent Chemical Resistance – Resistant to acids, alkalis, organic solvents, and steam.

Mechanical Strength & Stiffness – Maintains dimensional stability under stress and heat.

Wear & Abrasion Resistance – Ideal for moving parts, bearings, and seals.

Electrical Insulation – High dielectric strength for electronic and electrical components.

Lightweight & Durable – Easier to machine and transport than metal equivalents.

Applications of PEEK Plastic

Aerospace & Automotive

High-performance engine components

Bearings and bushings

Fuel system parts

Electronics & Electrical

Insulators and connectors

Circuit board components

High-temperature wire guides

Medical & Healthcare

Surgical instruments and implants

Sterilizable medical components

Components for diagnostic equipment

Industrial & Mechanical

Pump and valve parts

Wear-resistant machinery components

PEEK plastic machining for custom precision parts

Additive Manufacturing

What is PEEK material used for? PEEK is used in 3D printing and additive manufacturing for creating durable, high-temperature-resistant components for aerospace, automotive, and medical applications.

Why Choose Our PEEK Material?

As experienced PEEK manufacturers, we provide:

High-quality PEEK plastic material with consistent properties

Reliable supply for small-batch prototyping and large-scale production

Technical support for PEEK plastic machining and processing

Customized grades to meet specific thermal, mechanical, or chemical requirements

Choosing our PEEK ensures: longevity, reliability, and performance in high-demand applications.

FAQs

Q1: What is PEEK material?

A1: PEEK is polyetheretherketone, a high-performance thermoplastic with excellent heat, chemical, and mechanical resistance.

Q2: What material is PEEK made of?

A2: PEEK is made from aromatic ether and ketone monomers, forming a semi-crystalline polymer chain.

Q3: What is PEEK material used for?

A3: Used in aerospace, automotive, electronics, medical, industrial machinery, and additive manufacturing.

Q4: Can PEEK plastic be machined?

A4: Yes, PEEK plastic machining is possible with standard CNC techniques using sharp tools due to its high wear resistance.

Q5: Why choose PEEK over other polymers?

A5: PEEK offers superior thermal resistance, chemical stability, mechanical strength, and electrical insulation compared to many engineering plastics.