Polyetheretherketone (PEEK): A High-Performance Engineering Polymer

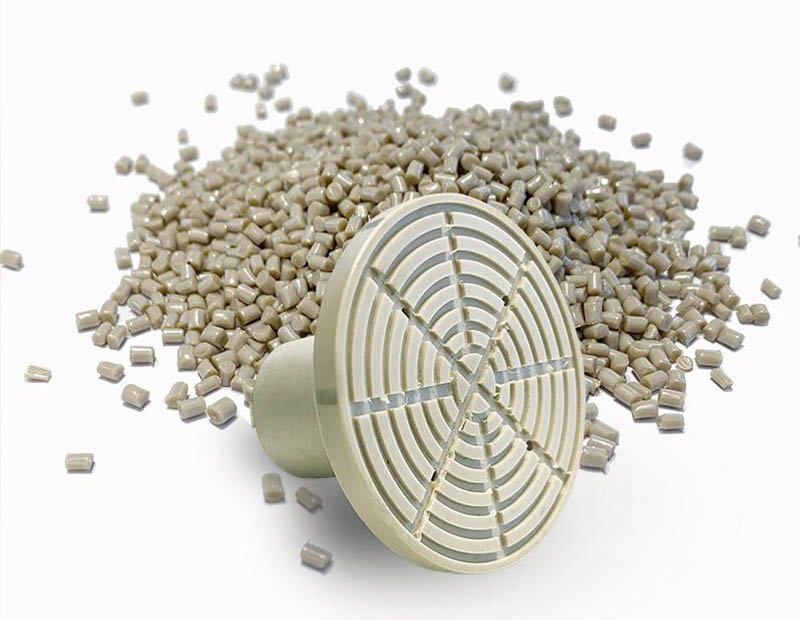

Polyetheretherketone (PEEK) is a semi-crystalline thermoplastic polymer belonging to the polyaryletherketone (PAEK) family. Developed in the late 1970s by Victrex PLC, PEEK has become one of the most widely used high-performance polymers due to its exceptional combination of mechanical, thermal, and chemical properties.

Key Characteristics of PEEK

1. Mechanical Properties

PEEK exhibits outstanding mechanical strength and stiffness. Its tensile strength ranges from 90-100 MPa, with a flexural modulus of 3.6-4.0 GPa. The material maintains these properties across a wide temperature range, with only 15-20% reduction in tensile strength at 150°C compared to room temperature.

2. Thermal Stability

PEEK has a glass transition temperature (Tg) of 143°C and a melting point of 343°C. It can operate continuously at temperatures up to 250°C and withstand short-term exposure to 300°C. The thermal conductivity is approximately 0.25 W/m·K, while the coefficient of thermal expansion ranges from 40-60 × 10-6/°C.

3. Chemical Resistance

PEEK demonstrates excellent resistance to most organic and inorganic chemicals, including hydrocarbons, acids, and bases. It shows less than 1% weight gain after 24 hours immersion in water at 23°C and maintains good dimensional stability with water absorption typically below 0.5% at saturation.

4. Wear and Friction Properties

With a coefficient of friction against steel of approximately 0.2-0.3 and excellent wear resistance (specific wear rate of 1-5 × 10-6 mm3/Nm), PEEK is ideal for tribological applications. These properties can be further enhanced with fillers like carbon fiber or PTFE.

5. Electrical Properties

PEEK has a volume resistivity of 1016 Ω·cm, dielectric strength of 20 kV/mm, and dielectric constant of 3.2-3.3 at 1 MHz, making it suitable for high-voltage electrical applications.

Applications of PEEK

Aerospace Industry

PEEK is extensively used in aerospace components due to its lightweight nature (density of 1.32 g/cm3) and flame resistance (UL94 V-0 rating). Applications include:

Cable insulation for aircraft wiring

Bearing retainers and bushings

Fuel system components

Structural brackets and fasteners

Medical Applications

PEEK's biocompatibility (ISO 10993 certified) and radiolucency make it ideal for medical devices:

Spinal fusion cages with elastic modulus (3-4 GPa) similar to cortical bone

Dental healing abutments and prosthetics

Surgical instrument components sterilizable by autoclave (up to 134°C)

Trauma fixation devices

Oil and Gas Industry

PEEK components withstand harsh downhole conditions:

Seals and back-up rings for pressures up to 20,000 psi

Electrical connectors in logging tools

Valve seats and wear rings

Insulators for high-temperature sensors

Automotive Sector

PEEK helps reduce weight and improve efficiency:

Transmission components (gears, thrust washers)

Turbocharger components

Fuel system parts (pump gears, valve plates)

Electrical connectors in engine compartments

Electronics and Semiconductor

PEEK's purity and thermal stability are valuable in electronics:

Wafer carriers and handling components

Insulators for high-voltage connectors

Coil bobbins and sensor housings

3D printing of functional prototyPES

Maintenance and Care of PEEK Components

Cleaning Procedures

For optimal performance and longevity:

Use mild detergents or isopropyl alcohol for cleaning

Avoid strong acids (concentration > 60%) and oxidizing agents

Ultrasonic cleaning is effective at frequencies below 40 kHz

For medical applications, follow validated sterilization protocols

Storage Conditions

Proper storage prevents degradation:

Store in original packaging at temperatures below 40°C

Maintain relative humidity below 50%

Protect from UV exposure to prevent surface degradation

For critical applications, dry parts at 150°C for 4 hours before use if exposed to moisture

In-Service Monitoring

Regular inspection helps identify wear or damage:

Check for surface cracks or discoloration indicating thermal degradation

Monitor dimensional changes exceeding 0.5% in critical applications

For bearing applications, measure wear depth not exceeding 0.1 mm

In electrical applications, verify insulation resistance remains above 1012 Ω

Replacement Guidelines

Consider replacement when:

Visible cracks or permanent deformation occurs

Wear exceeds 10% of critical dimensions

Chemical exposure causes swelling above 2% by volume

Electrical properties degrade beyond acceptable limits