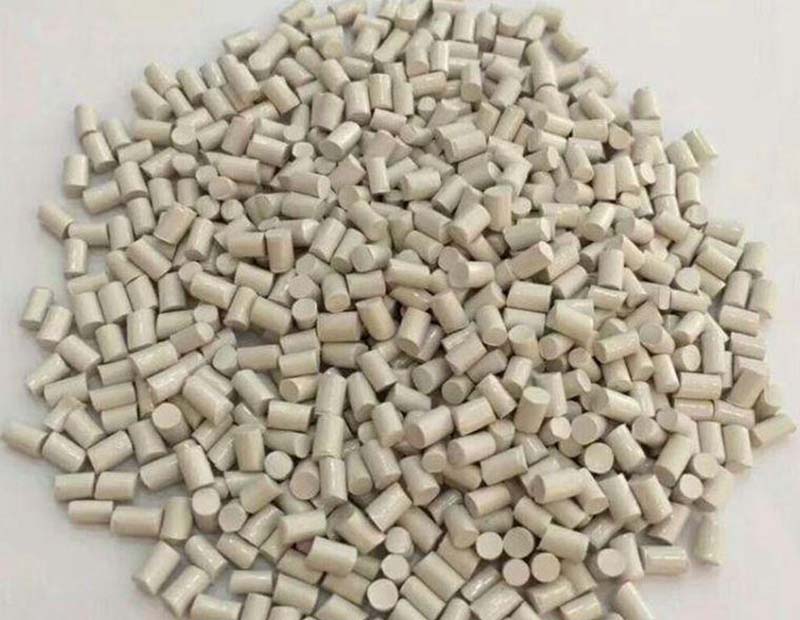

PEEK Plastic: Properties, Applications, and Maintenance

Introduction to PEEK

Polyether Ether Ketone (PEEK) is a High-performance thermoplastic polymer belonging to the polyaryletherketone (PAEK) family. This semi-crystalline material is renowned for its exceptional combination of mechanical, thermal, and chemical resistance properties, making it suitable for demanding applications across various industries.

Key Characteristics of PEEK

Mechanical Properties

PEEK exhibits outstanding mechanical strength with a tensile strength of 90-100 MPa and flexural strength of 170 MPa. Its Young's modulus ranges between 3.6-4.0 GPa, providing excellent stiffness. The material maintains these properties up to 250°C, with only minimal degradation at elevated temperatures.

Thermal Properties

PEEK has a glass transition temperature (Tg) of 143°C and a melting point of 343°C. Its continuous service temperature reaches 260°C in air, with short-term exposure tolerance up to 300°C. The thermal conductivity is 0.25 W/m·K, while the coefficient of thermal expansion measures 47×10⁻⁶/°C.

Chemical Resistance

PEEK demonstrates remarkable resistance to most organic and inorganic chemicals, including hydrocarbons, alcohols, and many acids at moderate concentrations. It maintains stability in pH ranges from 1 to 14, except against concentrated sulfuric acid and nitric acid. The material also shows excellent resistance to hydrolysis, even in high-pressure steam environments up to 260°C.

Electrical Properties

With a dielectric strength of 19 kV/mm and volume resistivity of 10¹⁶ Ω·cm, PEEK serves as an excellent electrical insulator. Its dielectric constant remains stable at 3.2-3.3 across a frequency range of 50 Hz to 1 MHz.

Wear and Friction Properties

PEEK exhibits a low coefficient of friction (0.3-0.4) against steel and excellent wear resistance. When reinforced with carbon fibers, its wear resistance improves by 100-fold, making it suitable for bearing applications.

Applications of PEEK

Aerospace Industry

PEEK replaces metal components in aircraft due to its high strength-to-weight ratio and flame retardancy (UL94 V-0 rating). Applications include cable insulation, bushings, valve seats, and structural components in engines, where weight reduction is critical.

Medical Applications

PEEK's biocompatibility (ISO 10993 compliant) and radiolucency make it ideal for medical implants, including spinal fusion devices, trauma fixation products, and dental instruments. Its modulus (3-4 GPa) closely matches human bone, reducing stress shielding effects.

Oil and Gas Industry

In downhole applications, PEEK components withstand extreme pressures (>15,000 psi) and temperatures (>200°C). It's used in seals, valve components, and electrical connectors for subsea equipment.

Semiconductor Manufacturing

PEEK's ultra-high purity and chemical resistance make it suitable for wafer carriers, robotic end effectors, and fluid handling components in cleanroom environments. Its low outgassing properties (<10⁻⁶ Torr·L/s·cm²) prevent contamination.

Automotive Sector

PEEK replaces metal in transmission components, turbocharger parts, and bearing cages. Its ability to withstand engine compartment temperatures (>150°C) and resist automotive fluids makes it valuable for under-the-hood applications.

Food Processing

PEEK meets FDA and EU 10/2011 compliance for food contact applications. It's used in pump components, valve seats, and conveyor system parts where steam sterilization (>120°C) is required.

Maintenance and Care of PEEK Components

Cleaning Procedures

For general cleaning, use mild detergents or isopropyl alcohol. Avoid abrasive cleaners that might scratch the surface. For sterilization, autoclaving at 134°C for 5 minutes or gamma radiation at 25-50 kGy is effective.

Storage Conditions

Store PEEK components in a clean, dry environment at temperatures below 80°C. Avoid prolonged exposure to UV radiation, which may cause slight surface degradation. For critical applications, maintain relative humidity below 50%.

Inspection and Maintenance

Regularly inspect PEEK components for:

Surface cracks or crazing, especially in load-bearing applications

Discoloration indicating potential thermal degradation

Dimensional changes beyond tolerance limits

Increased friction or wear in moving parts

Replacement Guidelines

Replace PEEK components when:

Visible cracks exceed 0.5 mm in depth

Wear exceeds 10% of critical dimensions

Performance degradation affects system operation

After 5-10 years in continuous high-temperature service

Special Considerations for Machined PEEK Parts

When maintaining machined PEEK components, avoid overtightening fasteners (recommended torque values typically 20-30% lower than for metals). For threaded connections, use thread-locking compounds compatible with high temperatures. Periodically check and re-torque connections after initial installation as PEEK may experience slight creep under continuous load.