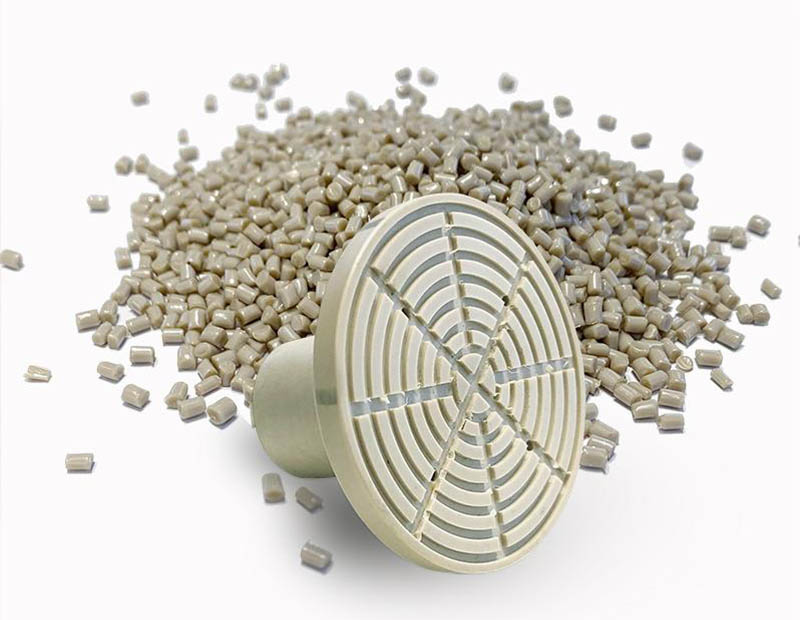

What is PEEK Raw Material?

PEEK Raw Material has gained widespread recognition as one of the most versatile and high-performance engineering plastics. PEEK, short for Polyether Ether Ketone, belongs to the family of semi-crystalline thermoplastics, known for its exceptional mechanical strength, chemical resistance, and thermal stability. These qualities make PEEK raw materials suitable for a wide range of demanding applications in medical, aerospace, automotive, and industrial sectors.

Definition and Overview

PEEK raw materials are High-performance thermoplastics that maintain structural integrity under extreme temperatures, chemical exposure, and mechanical stress. Unlike conventional plastics, PEEK provides long-term durability while being lightweight and resistant to wear. As a high-performance plastic, PEEK has emerged as a preferred choice for industries that require precision, reliability, and compliance with strict safety standards.

Chemical Structure

The molecular structure of PEEK consists of aromatic rings connected by ether (–O–) and ketone (–CO–) linkages. This arrangement contributes to its rigidity, dimensional stability, and high melting point, which is approximately 343°C. The semi-crystalline nature of PEEK raw materials also allows for excellent mechanical properties, including impact resistance, tensile strength, and fatigue resistance.

Key aspects of PEEK’s chemical structure include:

Aromatic backbone: Provides high dimensional stability and mechanical strength.

Ether linkages (–O–): Contribute to flexibility and toughness.

Ketone groups (–CO–): Enhance thermal and chemical resistance.

Basic Properties of PEEK Raw Materials

High Thermal Resistance: PEEK can withstand continuous operating temperatures of 250°C and short-term peaks up to 300°C, making it suitable for high-temperature applications such as engine components and sterilizable medical instruments.

Outstanding Chemical Resistance: PEEK raw materials are resistant to acids, bases, alcohols, and most organic solvents. This property ensures long-term performance even in harsh chemical environments.

Exceptional Mechanical Strength: PEEK exhibits high tensile strength, flexural strength, and fatigue resistance, maintaining performance under mechanical stress.

Wear and Abrasion Resistance: The material is highly resistant to wear, making it suitable for components like bearings, gears, and seals.

Flame Retardancy: PEEK meets UL94 V-0 standards for flame retardancy, a crucial requirement for electronics and aerospace applications.

Common Applications

Thanks to its remarkable properties, PEEK raw materials are applied across multiple industries:

Medical Devices: Surgical instruments, sterilizable trays, dental implants, and orthopedic components.

Aerospace: Engine components, structural parts, and electrical connectors, benefiting from high-temperature stability and weight reduction.

Automotive: Fuel system components, transmission parts, and bearings, where high wear resistance and chemical stability are essential.

Industrial and Electronics: Pumps, valves, gears, and housings requiring durability, dimensional stability, and resistance to harsh chemicals.

Advantages of Using PEEK Raw Materials

Compared to conventional plastics, PEEK offers:

Long-term durability under high temperatures and mechanical stress.

Resistance to repeated sterilization and chemical exposure.

Suitability for injection molding, extrusion, and 3D printing processes.

A lightweight alternative to metals without compromising strength and performance.

Selecting PEEK Raw Materials

When choosing PEEK raw materials, manufacturers consider:

Grade and Color: Standard or reinforced grades (e.g., carbon fiber or glass fiber-filled PEEK) for enhanced properties.

Mechanical Requirements: Tensile strength, impact resistance, and fatigue properties tailored to specific applications.

Compliance Standards: ISO, FDA, ASTM, and UL certifications for medical, food, or industrial applications.

Processing Method: Compatibility with injection molding, extrusion, or additive manufacturing processes

PEEK raw materials are High-Performance Thermoplastics that combine exceptional mechanical strength, chemical resistance, and thermal stability. Whether for medical devices, aerospace components, automotive parts, or industrial applications, PEEK provides a reliable solution where conventional plastics fail.

Investing in high-quality PEEK raw materials ensures enhanced product performance, extended service life, and compliance with global safety standards. As industries increasingly demand durable, lightweight, and high-temperature-resistant materials, PEEK remains a top choice for manufacturers worldwide.