PEEK (Polyether Ether Ketone) is a High-performance thermoplastic polymer known for its exceptional mechanical strength, chemical resistance, and thermal stability. Widely used in aerospace, automotive, medical, and electronics industries, PEEK plastic offers a combination of properties that few other materials can match, making it an ideal choice for demanding engineering applications.

What is PEEK Plastic?

PEEK is a semicrystalline engineering thermoplastic with high chemical and thermal resistance. It belongs to the polyaryletherketone (PAEK) family and is renowned for its superior mechanical performance under extreme conditions. Its combination of rigidity, strength, and stability allows it to replace metals in many high-performance applications.

Key Characteristics of PEEK:

High mechanical strength and stiffness

Excellent wear and abrasion resistance

Outstanding thermal stability (continuous use up to 250°C)

Excellent chemical and corrosion resistance

Low moisture absorption and excellent dimensional stability

Applications of High-Performance PEEK Plastic

1. Aerospace & Aviation

Components in aircraft engines, interiors, and structural parts

Replaces metals to reduce weight while maintaining strength

Resistant to high temperatures, fuels, and chemicals

2. Automotive & Transportation

Engine components, bearings, seals, and transmission parts

High-temperature resistance ensures long service life in engines and exhaust systems

Lightweight alternative to metals improves fuel efficiency

3. Medical & Healthcare

Surgical instruments, implants, and dental devices

Biocompatible and sterilizable

Excellent mechanical properties for load-bearing implants

4. Electronics & Electrical Engineering

Insulators, connectors, and semiconductor components

High dielectric strength and stability in harsh environments

5. Industrial & Chemical Processing

Pumps, valves, seals, and gears

Resistant to harsh chemicals, acids, and solvents

PEEK Raw Materials and Grades

PEEK is available in multiple forms and grades depending on the application requirements:

Natural PEEK: Unfilled, high-purity polymer for general engineering applications

Reinforced PEEK: Filled with glass fibers, carbon fibers, or PTFE for enhanced strength, wear resistance, or low friction

Medical-Grade PEEK: Biocompatible, FDA-approved for implants and medical devices

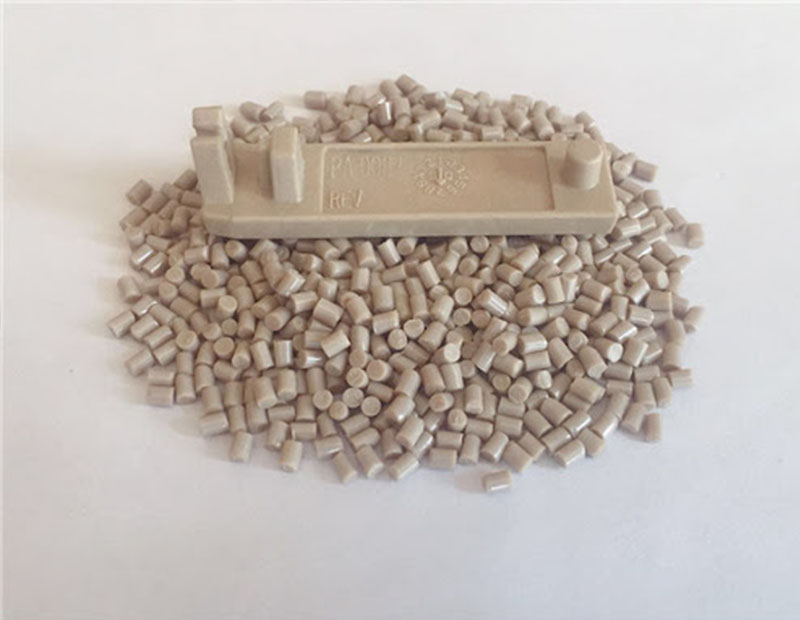

PEEK Powder & Pellets: Raw materials for injection molding, extrusion, or compression molding

Advantages of Using PEEK Material

| Advantage | Description |

|---|---|

| High Temperature Resistance | Continuous use up to 250°C without losing mechanical properties |

| Chemical Resistance | Resistant to acids, bases, oils, and organic solvents |

| Mechanical Strength | High tensile, flexural, and impact strength |

| Lightweight | Can replace metals in many applications |

| Dimensional Stability | Maintains precise dimensions under mechanical and thermal stress |

| Biocompatibility | Safe for medical implants and devices |

Why Choose High-Performance PEEK Plastic?

PEEK plastic is the material of choice for industries where performance cannot be compromised. Its combination of strength, chemical resistance, thermal stability, and low wear allows engineers to design components that are lightweight, durable, and reliable. Whether for aerospace, medical, automotive, or industrial machinery, PEEK ensures long-term performance under demanding conditions.

From PEEK raw materials to finished engineering components, High-Performance PEEK Plastic provides unmatched versatility for advanced applications. With its superior mechanical, thermal, and chemical properties, PEEK continues to be a critical material in modern engineering, enabling innovation in multiple industries.