PEEK (Polyether Ether Ketone) Plastic is a High-performance thermoplastic polymer widely used in industries requiring exceptional mechanical, thermal, and chemical resistance. Known for its remarkable combination of strength, stability, and processability, PEEK Material has become the material of choice for demanding applications in aerospace, automotive, medical devices, electronics, and industrial equipment.

As a trusted supplier of PEEK Raw Materials, we provide high-quality High-Performance PEEK Plastic and tailored solutions to meet the specific requirements of manufacturers and engineers worldwide.

1. Overview of PEEK Plastic

Polymer PEEK is a semi-crystalline engineering thermoplastic characterized by:

High Mechanical Strength: PEEK maintains its structural integrity under heavy loads and repeated stress.

Outstanding Thermal Stability: Operating temperatures up to 250°C (482°F) make it suitable for high-temperature applications.

Chemical Resistance: Resistant to acids, bases, solvents, and hydrolysis, ensuring longevity in harsh chemical environments.

Wear and Friction Resistance: Excellent for components exposed to high friction or sliding contact.

Lightweight Yet Durable: Offers high strength-to-weight ratio, ideal for aerospace and automotive parts.

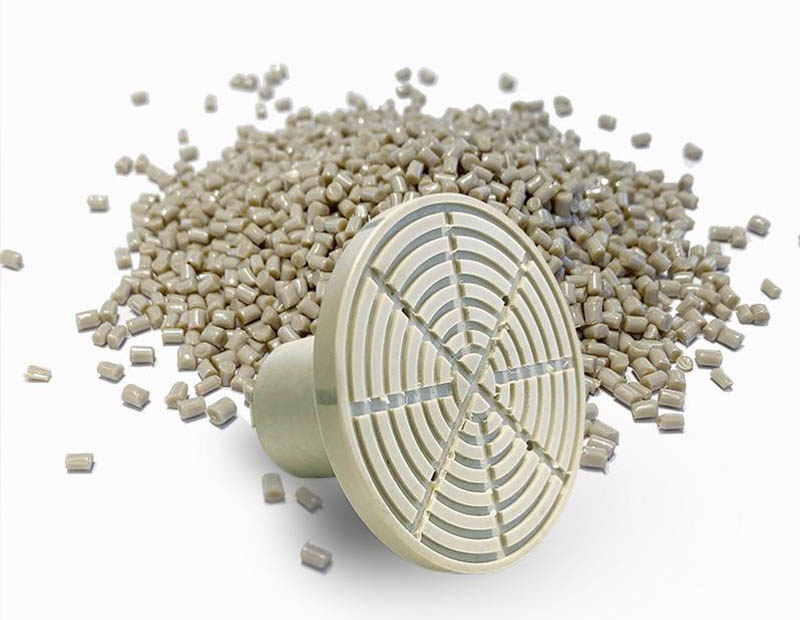

PEEK is available in various forms, including virgin resin, reinforced grades (carbon-fiber or glass-fiber), and modified compounds, allowing customization according to performance needs.

2. Key Features of High-Performance PEEK Material

High Mechanical and Tensile Strength – Maintains rigidity and dimensional stability even under extreme stress.

Superior Thermal Resistance – Continuous use in temperatures up to 250°C, with short-term resistance to even higher temperatures.

Excellent Chemical Resistance – Stable in contact with acids, alkalis, fuels, oils, and aggressive solvents.

Low Wear and Friction – Ideal for bearings, gears, seals, and sliding components.

Flame Retardant – Meets stringent fire safety standards without additional treatment in many grades.

Biocompatibility – Suitable for medical implants and devices (certain medical-grade PEEK).

Electrical Insulation – Excellent dielectric properties, suitable for electronic and electrical components.

3. Applications of PEEK Raw Materials

The versatility of PEEK Plastic makes it widely used in critical industries:

Aerospace: Structural components, bearings, seals, and electrical connectors that require high thermal and mechanical performance.

Automotive: Engine components, transmission parts, fuel system components, and wear-resistant bearings.

Medical Devices: Surgical implants, spinal cages, dental devices, and diagnostic equipment using medical-grade PEEK.

Electronics and Semiconductors: Insulators, connectors, and high-temperature circuit components.

Industrial Machinery: High-strength, chemical-resistant parts including pumps, valves, gears, and sliding elements.

By offering Polymer PEEK in different grades, including reinforced and modified options, manufacturers can optimize performance for specific applications.

4. Advantages of Choosing Our PEEK Materials

Premium Quality Raw Materials: Sourced and produced under strict quality control standards.

Consistent Mechanical and Thermal Properties: Ensures reliability in high-stress or high-temperature environments.

Customizable Grades: Reinforced, modified, or virgin PEEK available to suit any manufacturing process.

Global Supply and Support: Fast delivery and technical assistance for OEMs and industrial manufacturers.

Sustainability and Compliance: Materials comply with international standards including ISO and RoHS certifications.

5. Processing and Fabrication

PEEK Plastic can be processed using standard thermoplastic methods such as:

Injection molding

Extrusion

Compression molding

Machining and CNC processing

Its excellent thermal and chemical stability allows it to retain properties during demanding fabrication processes. Additionally, reinforced PEEK grades provide enhanced stiffness and wear resistance for high-performance engineering components.

6. Why Use PEEK for Advanced Applications

Using High-Performance PEEK Plastic offers unmatched advantages:

Reduces component weight while maintaining mechanical strength.

Enables parts to perform reliably under extreme conditions (high temperature, chemical exposure, high stress).

Offers long service life with minimal maintenance.

Provides flexibility in design through machinable or moldable grades.

Meets demanding industrial, aerospace, and medical regulatory standards.

PEEK Raw Materials are essential for industries that demand superior performance, durability, and precision. Whether you require Polymer PEEK for medical devices, automotive components, aerospace parts, or industrial machinery, our High-Performance PEEK Plastic offers reliable and consistent properties for critical applications.

As a professional supplier of PEEK Material, we provide technical support, tailored grades, and high-quality raw materials to ensure your products meet the highest standards of performance and reliability.

For more information about available grades or custom PEEK solutions, please contact our sales or technical team for consultation.