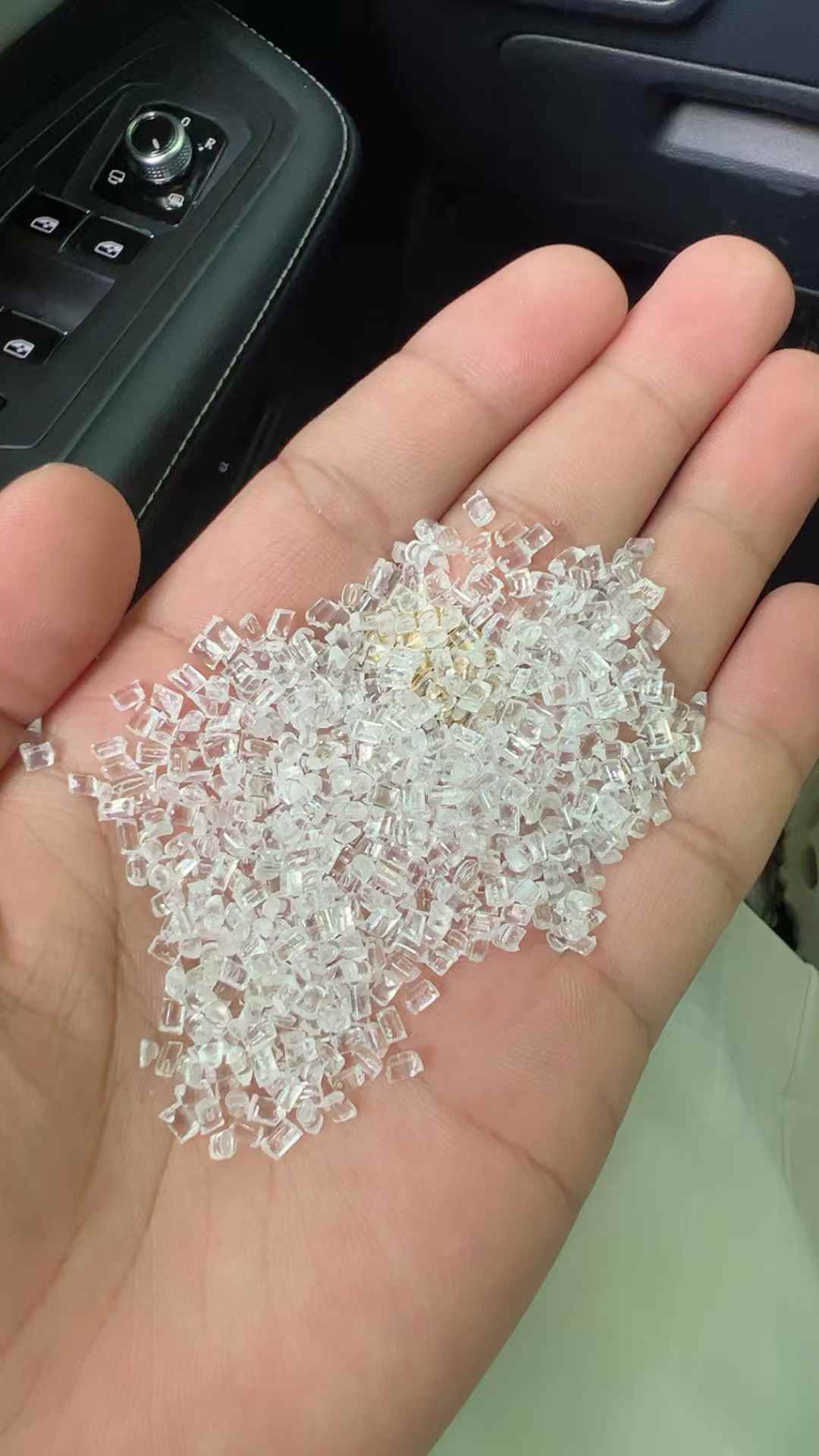

Polyphenylsulfone (PPSU) is a premium-grade, high-performance engineering thermoplastic known for its outstanding physical, thermal, and chemical properties. It is widely used in industries that demand durability and reliability, including medical, aerospace, food processing, electronics, and fluid handling systems. Compared to conventional thermoplastics, PPSU offers superior impact resistance, higher thermal stability, and excellent chemical resistance, making it ideal for use in extreme environments.

Excellent High-Temperature Resistance: PPSU maintains structural integrity at continuous-use temperatures up to 260°C and can withstand repeated steam sterilization without deformation or performance degradation.

Superior Chemical Resistance: It resists attack from acids, alkalis, alcohols, disinfectants, and other harsh chemicals, making it suitable for use in medical and laboratory equipment.

Outstanding Hydrolysis Resistance: PPSU does not degrade in hot water or steam over time, ensuring long-term reliability in sterilizable products.

High Impact Strength: PPSU offers significantly higher impact resistance than PSU, PEI, and other similar materials, with excellent toughness under mechanical stress.

BPA-Free and Food-Safe: As a non-toxic, BPA-free material, PPSU is ideal for use in food contact applications and baby care products.

Good Processability: PPSU supports injection molding, extrusion, and machining, allowing complex parts to be produced with precision and consistency.

Medical Devices: Surgical instrument handles, syringes, endoscopic components, dental equipment, reusable sterilizable tools

Baby Products: PPSU baby bottles, sippy cups, straw cups

Food Contact Applications: Food processing equipment components, containers, sanitary pipe fittings

Aerospace and Industrial: Lightweight high-temperature parts, structural components, electrical connectors

Laboratory and Pharmaceutical Equipment: Chemical containers, fluid systems, valves, fittings

| Property | Typical Range |

|---|---|

| Density | 1.29 g/cm³ |

| Heat Deflection Temperature | 207 – 220°C |

| Glass Transition Temperature | 220 – 230°C |

| Tensile Strength | 55 – 75 MPa |

| Flexural Modulus | 2100 – 2300 MPa |

| Notched Impact Strength | 60 – 80 kJ/m² |

| Continuous Use Temperature | -50°C to 180°C |

| Flammability Rating | UL94 V-0 (at 1.5mm) |

Note: Values may vary depending on the grade and processing method.

Reliable Stock Supply: We offer various grades, colors, and specifications suitable for medical and food-grade requirements

Custom Fabrication Support: We provide molded parts, rods, sheets, and semi-finished products tailored to your needs

Certified Quality: PPSU materials meet international standards such as FDA, ISO 10993, RoHS, and REACH

Technical Expertise: Our experienced engineers provide full support for product development and material selection

Polyphenylsulfone (PPSU) is a high-performance thermoplastic material known for its exceptional mechanical properties, high thermal stability, chemical resistance, and durability. It is commonly used in demanding industries like medical, aerospace, automotive, and food processing.

PPSU offers excellent thermal stability (up to 180°C), high mechanical strength, good chemical resistance, hydrolytic stability, low shrinkage, transparency, and good electrical insulating properties. It can also withstand repeated sterilization cycles, which makes it ideal for medical applications.

PPSU is used in a variety of industries, including medical (for surgical instruments, catheters, and sterilization trays), automotive (for engine parts, fuel system components), aerospace (for airframe and engine parts), and food processing (for containers, dispensers, and cookware).

PPSU is highly biocompatible and can withstand repeated sterilization cycles, including autoclaving. Its chemical resistance and strength make it an excellent material for medical devices, such as surgical instruments, catheters, and fluid management systems, where reliability and hygiene are critical.

While both PPSU and PEEK are high-performance materials, PPSU has a higher glass transition temperature (Tg), making it better suited for certain high-temperature applications. PEEK, however, has superior mechanical strength and is more resistant to wear. PPSU is generally more affordable and offers excellent chemical resistance and hydrolytic stability.

Yes, PPSU is FDA-compliant and can be used in food contact applications. It is resistant to high temperatures, staining, and degradation from food products, making it ideal for items like food containers, dispensing systems, and cooking equipment.